Inventory is the lifeblood of most firms, yet it is frequently a hidden drain on profits. Too much inventory clogs your cash flow, accumulates dust, and may become outdated. Too little, and you’ll lose revenue and upset clients. Finding that “sweet spot”—the ideal balance of having enough without having too much—is about more than just managing items; it’s also about maximizing your financial health and maintaining consistent growth.

This article explores the critical inventory optimization tactics that can transform your stockroom from a cost center to a powerful engine for optimal profitability.

Why bother with the imperative for optimization?

Why devote time and effort to improving your inventory? The benefits have a direct influence on your bottom line.

- Reduced Carrying Costs: Excess inventory has considerable expenses, including storage, insurance, security, potential damage, and obsolescence. Optimization reduces these costs.

- Improved Cash Flow: Capital locked up in stagnant stock cannot be used for investments, marketing, or growth. Freeing up this cash boosts your company’s performance.

- Enhanced Customer Satisfaction: Consistent product availability entails completing orders quickly, eliminating backorders, and increasing customer loyalty.

- Reduced Obsolescence and Shrinkage: Optimized inventory means less dead stock that loses value over time, and tighter control means fewer losses due to theft or damage.

- Improved operational efficiency: Streamlined inventory operations result in speedier order fulfillment, fewer human mistakes, and an organized warehouse.

- Better Decision-Making: With accurate, real-time inventory data, you can make informed decisions about purchasing, pricing, and promotions.

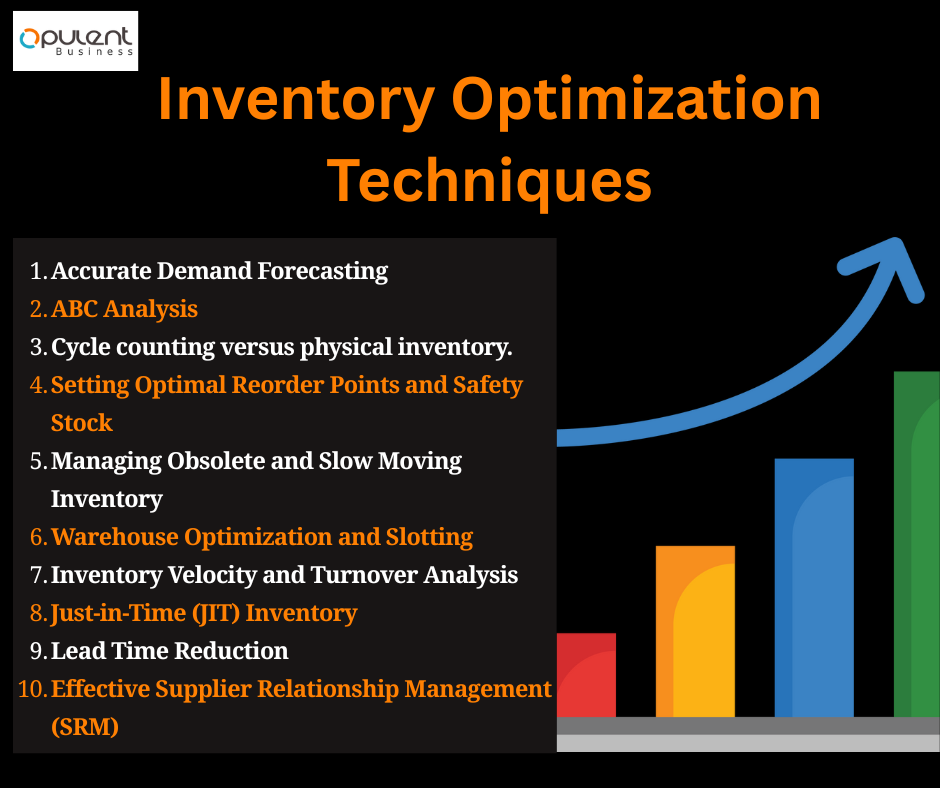

Key Inventory Optimization Techniques

Mastering your stock levels requires a combination of smart techniques.

- Accurate Demand Forecasting

The key to inventory optimization is properly forecasting what your consumers will want and when. This includes examining past sales data, recognizing seasonal trends, accounting for market changes, and adding qualitative inputs like promotional plans or economic projections. Modern ERP systems and specialist forecasting tools use statistical models and even AI/ML to deliver more exact demand estimates, moving away from guesswork. - ABC Analysis

Not all inventory items are created equally. ABC analysis divides your inventory into three groups according to its worth and importance: A-items: Items with a high value but low volume (such as core products). These necessitate the strictest management, regular assessments, and precise forecasts.

B-items: Items with a medium value and volume. They require modest control.

C-items are goods that are low in value but high in volume (for example, common consumables). These allow for more relaxed management and bulk purchases. This strategy guarantees that you concentrate your efforts where they will provide the highest return. - Setting Optimal Reorder Points and Safety Stock

A reorder point is the inventory level at which a fresh order should be made to refill supplies. It is determined using lead time (the time required to obtain fresh supply) and daily demand. Safety stock is an additional buffer of inventory maintained on hand to prevent stockouts caused by unanticipated demand surges or supply delays. Calculating them effectively, which is commonly automated by an ERP system, aids in maintaining targeted service levels while avoiding overstocking. - Just-in-Time (JIT) Inventory

The JIT philosophy aims to receive goods only as they are needed for production or direct sale, thereby minimizing inventory holding costs. This lean approach requires incredibly reliable suppliers, efficient logistics, and seamless communication. While it offers significant benefits in reducing carrying costs and waste, it also increases vulnerability to supply chain disruptions if not managed meticulously.

- Effective Supplier Relationship Management (SRM)

Your inventory performance is intrinsically linked to your suppliers. Building strong, collaborative relationships with key suppliers can lead to- Shorter, more reliable lead times.

- Improved quality of incoming goods.

- Flexible delivery schedules.

- Better pricing terms. These factors directly impact your ability to implement JIT, reduce safety stock, and respond quickly to market changes.

- Cycle counting versus physical inventory.

Even with powerful systems, physical counts are required to guarantee that inventory records reflect reality.Cycle counting is a continuous procedure in which a small amount of inventory is counted each day or week. This is less disruptive than complete counts, helps to detect differences early, and maintains superior accuracy over time.

Physical Inventory: A comprehensive count of all inventory, usually done once a year. While disruptive, it offers a thorough reconciliation. Both technologies detect disparities, allowing you to analyze the underlying reasons and optimize procedures. - Inventory Velocity and Turnover Analysis

Inventory turnover is the number of times inventory is sold or utilized during a given time period (for example, one year). It is determined by dividing the cost of goods sold (COGS) by the average inventory value. A high turnover often implies effective inventory management and good sales, whereas a low turnover may imply slow-moving or outmoded product. Analyzing these indicators helps to find inefficiencies and areas for improvement. - Warehouse Optimization and Slotting

Inventory management is greatly influenced by the efficient physical organization of your warehouse space. Warehouse optimization is developing the layout to provide the most efficient flow of commodities. Slotting is the systematic positioning of goods depending on picking frequency, size, and weight to save trip time and increase picking efficiency. Features commonly found in warehouse management systems (WMS) that are coupled with ERPs can help with these improvements, lowering operating costs and increasing fulfillment speed. - Managing Obsolete and Slow Moving Inventory

Identifying and managing outdated (no longer sellable) or slow-moving (sales occur seldom) inventory is critical for releasing money and storage space. To identify these things, perform aging reports on a regular basis (most ERPs have these). Strategies include aggressive discounts or bundling.

b. Returning products to the sellers.

c. Donation or proper disposal.

d. Writing off inventory to clear financials. - Lead Time Reduction

Lead time is the total amount of time from initiating an order (e.g., placing a purchase order) to actually receiving the goods and having them ready for use or sale. By reducing lead times, businesses can:- Lower their safety stock requirements.

- Respond more quickly to changes in demand.

- Improve overall supply chain responsiveness. This can involve working closer with suppliers, streamlining internal receiving processes, or exploring local sourcing options.

The enabling role of technology: your ERP system.

Without the appropriate technology, it would be extremely difficult, if not impossible, to successfully implement these optimization strategies. This is where an ERP (Enterprise Resource Planning) system becomes vital.

- Centralized Data: An ERP system creates a single, unified database for all inventory information, eliminating silos and ensuring data integrity across all departments.

- Automation: ERPs automate common processes, such as creating purchase orders and deducting stock upon sale, which reduces manual mistakes and saves time.

- Advanced Analytics and Reporting: ERPs include robust reporting capabilities and customizable dashboards that provide real-time insights into inventory valuation, turnover rates, aging, and other metrics, enabling data-driven choices.

- Seamless Integration: An ERP combines inventory with other essential modules such as sales, purchasing, accounting, and even manufacturing, providing a complete picture of your company and improving the whole supply chain.

- Visibility: Get real-time visibility into stock levels across all locations, allowing you to fulfill orders more effectively and manage scattered inventory.

Challenges and Best Practices for Inventory Optimization

While the benefits are evident, optimization presents challenges:

- Data Inaccuracy: Poor data hygiene (improper counts, incorrect item descriptions) can sabotage any optimization attempt.

- Poor forecasting involves relying too heavily on intuition or out-of-date models.

- Lack of Integration: Siloed departments result in disconnected inventory procedures.

- Resistance to Change: Employees may be comfortable with old methods.

To overcome this, implement the following recommended practices:

- Invest in accurate data gathering and management.

- Continuously analyze and improve your forecasting models.

- Encourage effective cross-functional collaboration across sales, marketing, procurement, and operations.

- Provide extensive and ongoing inventory training to all staff members.

- Begin small with a pilot program for a certain product line, then expand.

Conclusion: From Stockroom to Strategic Advantage.

Inventory is a valuable asset for any business, but it can rapidly turn into a problem if not handled properly. By using these inventory optimization tactics and harnessing the power of an ERP system, you can turn your stockroom from a cost center to a valuable strategic asset.

For businesses seeking to enhance their inventory management strategies, Opulent offers insights and solutions to guide your journey.